leave a message

KINGTECH TUBE MILL CO. LTDPrivacy statementTerms & conditionssitemap

KINGTECH TUBE MILL CO. LTD

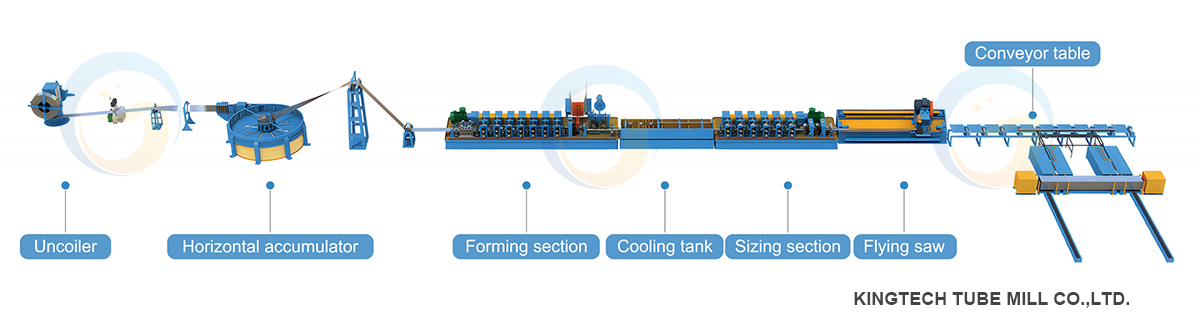

High frequency welding tube production line, also known as erw tube mill machine, is an advanced set of equipment used to produce carbon steel and galvanized steel pipes with high efficiency and precision.

The process involves feeding steel strips into the forming mill, where they are gradually formed into round shapes through a series of rollers. Once the edges of the strip meet, they are welded together using high-frequency induction technology. This ensures strong, durable, and smooth weld seams without the need for additional filler materials.

The advantage of high frequency welding tube mill lines in its speed and reliability. Compared with traditional welding methods, HF welding allows for continuous production at much higher speeds, making it ideal for large-scale manufacturing. Depending on the mill type, the machines can produce pipes of various diameters and wall thicknesses, serving industries such as construction, furniture, automotive, and oil & gas.

In addition, modern pipe mills are highly customizable. KINGTECH Tube Mill Manufacturer can choose models that meet their specific production range—whether for small precision tubes or larger industrial pipes. Advanced tube mills can also integrate online testing systems like eddy current testing to ensure quality control during production.

For businesses aiming to expand their carbon steel and galvanized steel pipe production, investing in a high frequency welding pipe mill is a strategic move. Not only does it boost production capacity, but it also reduces waste, improves product consistency, and ensures long-term profitability.

If you looking for high-frequency welded pipe production lines, contact us to get the quotation.